May 27,2024

Quickly adjust track tension in just 4 easy steps

The track is widely used in various construction machinery and equipment. The track is too loose or too tight, which will affect the normal walking of the equipment. Therefore, it is necessary to adjust the tension of the track regularly to ensure the longer service life of the equipment.

May 27,2024

For novices, hoisting is a very dangerous job. The following places to pay attention to must be remembered!

May 27,2024

Industrial machinery gear is an important part in the field of industrial automation, among which harmonic gear and cycloidal gear are widely used in robot rotary joint and hydraulic system respectively. The harmonic gear is composed of rigid gear, harmonic generator and flexible gear. The flexible gear rotates along the inner teeth of the rigid gear. Cycloidal gear has gradually become a new power in the field of industrial automation due to its characteristics of high efficiency, low noise, long life and easy maintenance.

May 27,2024

The use of industrial machinery gears

Industrial machinery gear is an important part of industrial machinery, its main uses include: Actuators: Gears in actuators such as manipulators, wrists and bases allow for precise positioning and flexible use of micro electronic gears. Driving mechanism: The gear plays a driving role in the driving mechanism, such as the driving wheel inside the wheel structure robot enterprise.

May 27,2024

Industrial machinery gear application

Industrial machinery gears are widely used in many fields. In industrial robots, gears are used in structures such as actuators, drive systems, control systems and sensing systems. The insertion and addition of gears make the positioning of the manipulator more accurate and flexible. In the medical field, gears have excellent mechanical properties, such as radiation resistance, low particle formation, wear resistance, chemical resistance and toxicity resistance, so they are widely used in three-dimensional imaging systems and dialyzer pumps.

May 27,2024

Working time parameters of excavator and parts maintenance plans

Check the oil level, open the fuel switch, and confirm (lubricating oil, fuel) with or without leakage.

May 27,2024

Excavator lost arm 7 reasons, 5 solutions are here!

Sometimes you will encounter the situation where the excavator has lost its arm. In the end, will your excavator lose its arm? How to solve the problem of arm failure?

May 27,2024

Motorcycle sprocket properly installed

The correct installation of a motorcycle sprocket involves the following steps: First, select the correct transmission sprocket model according to the model specifications. Second, check the location where the transmission sprockets are installed, such as the transmission output countershaft, wheel hub, etc., to ensure that they are in good condition. If necessary, replace the components. Then, install the main and driven sprockets in place according to the correct method, and tighten the fasteners so that they reach the specified force. When installing the chain, pay attention to the front and back sides of the chain to avoid the wrong installation leading to the chain breaking. In addition, pay attention to the direction of the inner guide and the outer guide to improve the strength of the chain. Finally, it is recommended that when replacing the motorcycle sprocket, watch the relevant car video tutorial in order to better understand the replacement technique.

May 27,2024

The number of teeth of the motorcycle sprocket

The number of sprocket teeth is one of the important parameters that affect the performance of motorcycle. According to the motorcycle, the more front gear teeth, the speed will be reduced, because the motorcycle is a fixed output power. When the number of teeth in the front disk is fixed, the more teeth in the back disk, the stronger the start, and the lower the tail speed; The smaller the number of teeth in the posterior disk, the weaker the start and the higher the tail speed. Motorcycle size sprocket teeth are generally very different, the small sprocket is the driving wheel, the general number of teeth is 13-15 teeth, the large sprocket for the driving wheel teeth is generally 30-50 teeth, the number of large sprocket teeth will be more, so that you can improve the output torque to help escape

May 27,2024

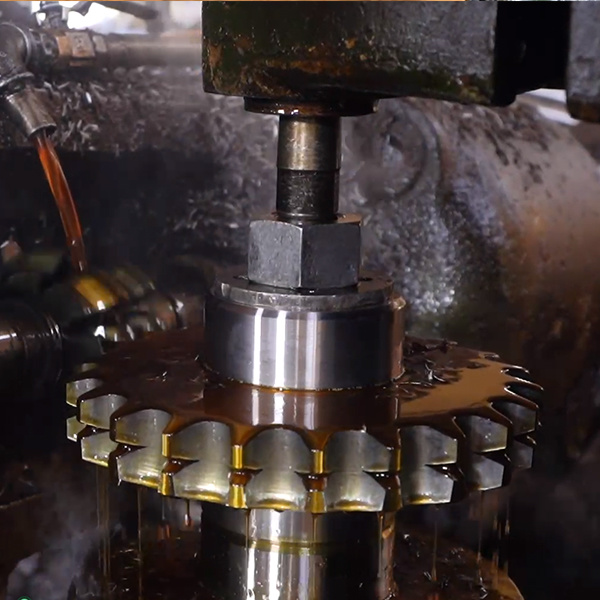

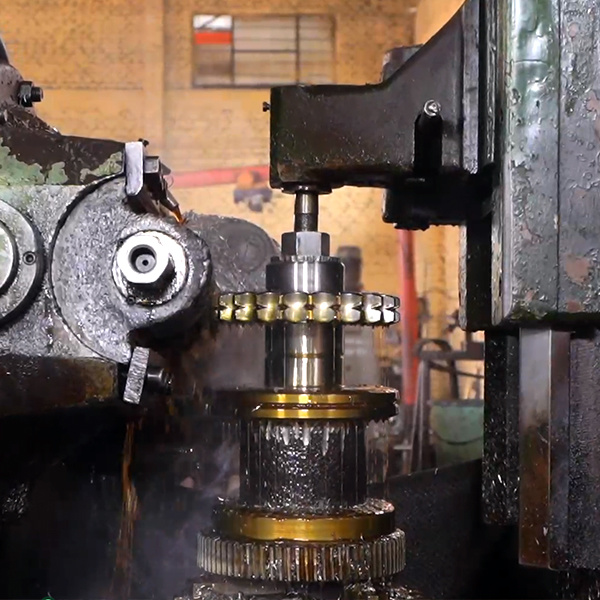

Motorcycle sprocket is an important part of the transmission system, choosing the right sprocket is crucial to the performance and service life of the motorcycle. The sprocket is divided into active sprocket and driven sprocket, the active sprocket is installed on the engine output shaft through the form of splines, the driven sprocket is installed on the motorcycle drive wheel, and the power is transmitted to the drive wheel through the chain. The sprocket material is usually made of high-quality carbon structural steel, which is milled and tempered heat treatment to improve its wear resistance and comprehensive mechanical properties.

Contact Us

E-mail:

Address:

No.130 Yun Zhuang Cun Xin Village, Luoyang Town, Tai Shang Tou Zi District, Quan Zhou City, Fu JianProvince, China